To ensure pipe work performs as designed for regardless of its age is key in any processing plant.

A suite of evaluation methods is available at 579 B.V. to evaluate pipe work ensuring compliance to local rules whilst safely being operated at the process intended performace. Integrity reviews are common practise for both existing and new pipework, whether the plant is 4 or 40 years old. Based on these evaluation methods, potential integrity issues can be identified upfront in order to avoid pipe work under performance and the associated unplanned plant outages .

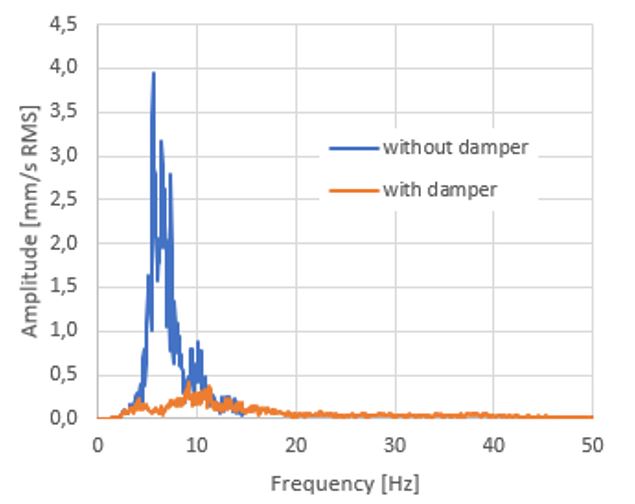

In example, one of the failure mechanisms is early failure from fatigue which is frequently caused by unexpected vibrations. Unexpected sources of vibrations are typically related to flow (i.e. Flow induced vibrations (FIV) or pulsations due to deadlegs ) or sound (i.e Acoustic induced vibrations (AIV)) which are both related to the process flow. Other well known possible vibration sources are:

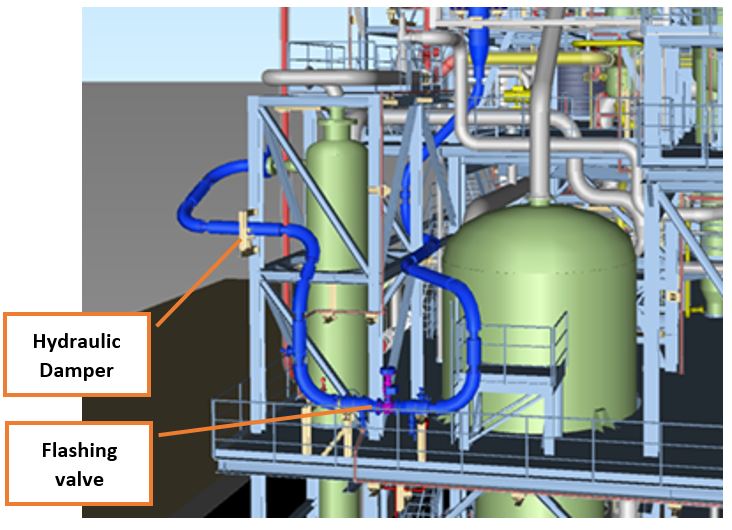

- Cavitation and flashing across a valve;

- Mechanical vibrations (pumps, compressors);

- Pipe work internals.

579 B.V. has extensive experience in both assessing and resolving these kinds of challenges in piping systems, includes the use of evaluation tools, on-site measurements and practical advice to ensure that required modifications are implemented successfully.

Other reasons to re-evaluate pipe work are process changes which result in operational conditions outside the design envelope driven by operational optimizations of the plant. 579 B.V. has experience in re-evaluating pipe work, especially if its operating outside the normal design conditions. This includes geometrical flaws like dents, local corrosion and crack like indications.

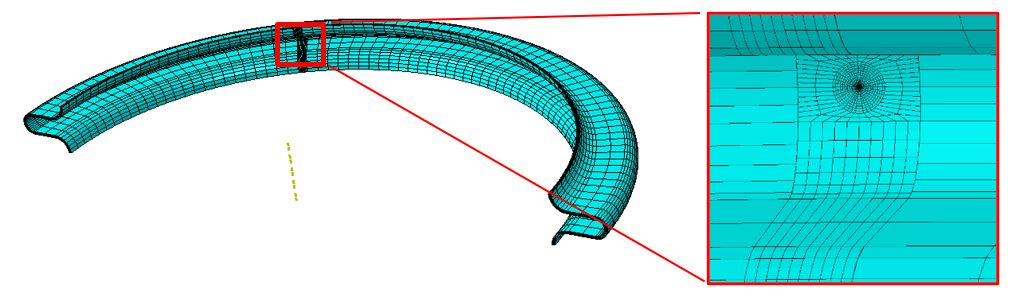

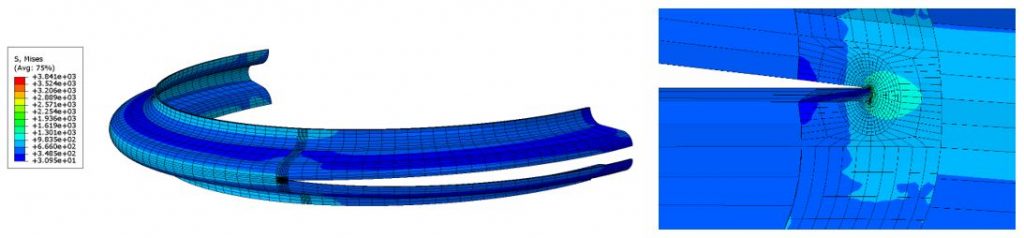

Besides the analytical evaluation methods, 579 B.V. is experienced in complex evaluation methods (level 3) which requires in-depth knowledge of the applied materials, interpreting inspection data, corrosion mechanisms and complex FEA analysis. In line with the API 579 guideline, typical flaws in a pipework or fittings can be assessed.