Fitness for Service (FFS) is a best practice and standard used by the oil & gas and chemical process industries for in-service equipment to determine its fitness for continued service.

Fitness for Service serves as a rational basis for defining flaw acceptance limits and allows engineers to distinguish between acceptable and unacceptable flaws and damage based on industry recognised and generally accepted good engineering practices (RAGAGEP).

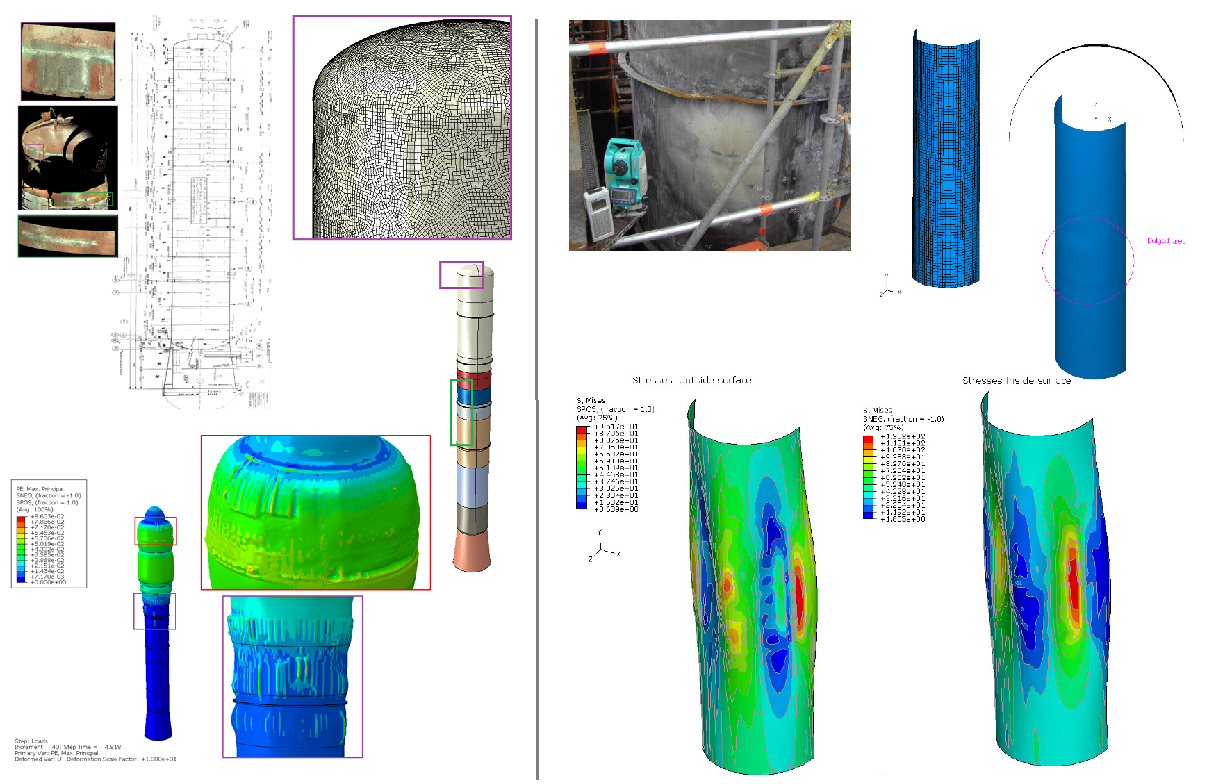

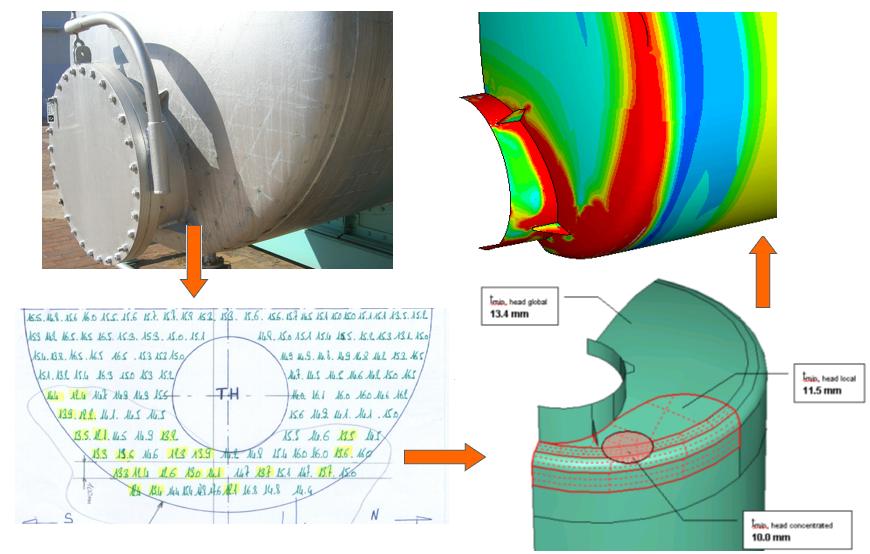

The fitness for service of any particular material is determined by performing a fitness-for-service assessment per standardised methods and criteria. Performing accurate Fitness for Service evaluations is an integral aspect of fixed equipment asset integrity management as an alternative to using the original construction design code. The fitness of a piece of equipment may be viewed both in terms of current and future fitness for service or remaining life.

Most equipment can continue in service despite small flaws, and to repair or replace equipment that can still be used would be an unnecessary and costly expense. In addition, unnecessary weld repairs can do more harm than good and create unnecessary risks to personnel in many cases.

API RP 579-1/ASME FFS-1, Fitness for Service, Second Edition, is one example of a FFS methodology currently used at 579 b.v. In general, most Fitness for Service assessment standards (for example API 579, BS7910, Fitnet) are broken into multiple levels. Each successive level (e.g., Levels 1, 2 and 3 of the referenced API 579-1/ASME FFS-1 standard) requires increasing amounts of data, calculations, effort, and cost to arrive at the most accurate outcomes and possible longer equipment remnant life.

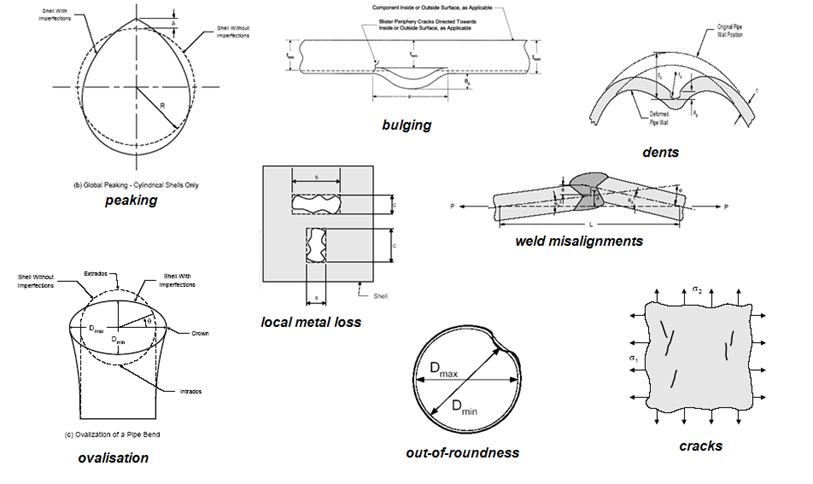

In addition to calculations, Fitness for Service assessments involves the consideration of additional data (e.g. pitting patterns and depths, corrosion morphology or shape and depth, crack depths and lengths, operating conditions, materials properties, etc.), in that respect inspection information is often critical input to a fitness for service assessment.

At 579 BV we have over 30 years of combined experience performing assessments against all international established codes and standards including client in-house performance standards of most majors in the petrochemical industry.

Our portfolio of reference projects deals with the full spectrum of the damage types covered in API RP 579, where our expertise is built around creep, (thermal or vibration induced) fatigue, crack like defects (fracture mechanics), severe metal loss and significant deviations from true shape.

Our strength is our ability to translate your complex engineering problems to practical solutions that are straightforward to implement and will help you to keep your assets safe and operational. In our experience fitness for service jobs are severely time constraint, so if you are in need for support with your assessments, please do not hesitate to contact us.